Power Supply and Electrical Systems in Electric Overhead Crane Operations

Electric Crane for sale. Check the voltage specifications, frequency considerations, and the impact of electrical systems on overhead crane operation.

Since the electric overhead cranes are vital for material handling across the dives of industrial sector. The significance of power supply and electrical systems cannot be overstated. Whether towering over construction sites or orchestrating heavy lifting in industrial settings, cranes rely fundamentally on electricity to function efficiently and safely.

Overview of Power Supply and Electrical Systems in Crane Operations:

Electric Cranes, regardless of their size or purpose, are intricately tied to electrical systems for their operations. These systems encompass a wide array of components, from motors to control systems, wiring, and distribution setups. The seamless integration of these elements ensures the smooth and safe functioning of cranes, allowing them to perform tasks with precision and reliability.

Importance of Understanding Voltage Requirements and Electrical Systems:

The heartbeat of crane operations lies in understanding the intricacies of voltage requirements and electrical systems. Voltage specifications are crucial, dictating the power input necessary for the crane to operate optimally. Incorrect voltage supply or fluctuations can hamper performance, compromise safety, and potentially lead to equipment damage. Therefore, a comprehensive grasp of these electrical aspects is imperative for crane operators, engineers, and maintenance personnel alike.

As we delve deeper into voltage specifications, frequency considerations, and the overarching impact of electrical systems on crane operation, we unravel the critical elements that ensure these mechanical marvels function seamlessly while prioritizing safety and efficiency.

Voltage Specifications

Definition and Importance of Voltage Requirements in Crane Operations:

Voltage requirements in crane operations refer to the specific electrical power levels necessary for optimal crane functionality. These requirements are pivotal as they directly influence the crane's performance, efficiency, and overall safety. Understanding the voltage needs ensures that the crane operates within the prescribed parameters, mitigating risks associated with inadequate or excess voltage supply.

Types of Voltage Requirements:

Standard Voltage Ratings:

- Cranes typically operate within predefined standard voltage ratings, which vary based on geographical locations or industry standards. These standard ratings serve as baseline requirements for the efficient functioning of the crane's electrical systems.

- Geographical and Industry Standards: Electrical systems for overhead cranes are designed to operate within predefined standard voltage ratings established by geographical regulations or industry standards. These ratings ensure compatibility, safety, and efficiency. Common standard voltage ratings can vary worldwide, such as 230V, 400V, 480V, 575V, or other regional specifications, depending on the country's electrical grid standards.

- Baselines for Operation: Standard voltage ratings serve as baseline requirements for the efficient functioning of the crane's electrical systems. These ratings are crucial for selecting appropriate electrical components, motors, drives, and control systems that align with the specified voltage levels.

- Safety and Compliance: Adhering to standard voltage ratings is essential for ensuring safety, compatibility with infrastructure, and compliance with regulatory standards, preventing overloading or damaging electrical components due to incompatible voltage levels.

Specialized Voltage Considerations:

Certain crane systems, like those incorporating variable frequency drives (VFDs), require specialized voltage considerations. VFDs enable precise speed control and energy efficiency by varying the frequency and voltage supplied to the crane's motor.

- Variable Frequency Drives (VFDs): Crane systems incorporating Variable Frequency Drives (VFDs) require specialized voltage considerations. VFDs play a pivotal role in regulating motor speed and torque by adjusting the frequency and voltage supplied to the crane's motor.

- Voltage Compatibility: VFDs enable precise speed control and energy efficiency by varying the frequency and voltage supplied to the motor. They require a compatible power supply that can accommodate the varying frequencies and voltage levels generated by the drives.

- Harmonics and Voltage Disturbances: VFDs can introduce harmonics and voltage disturbances into the electrical system, which may necessitate additional measures such as filters or harmonic mitigation devices to ensure stability and prevent adverse effects on other equipment within the electrical system.

- Voltage Quality: Ensuring the quality of the voltage supplied to VFDs is crucial for their proper operation. This includes maintaining stable voltage levels, adequate phase balance, and minimizing voltage fluctuations, which can affect the performance and lifespan of the drives.

In summary, standard voltage ratings provide baseline requirements for the efficient and safe operation of overhead crane electrical systems. However, specialized voltage considerations, particularly concerning VFDs, are essential for accommodating precise control, energy efficiency, and ensuring compatibility with these advanced control devices within the crane's electrical infrastructure.

Impact of Voltage Fluctuations on Crane Performance:

- Effects of Under or Over Voltage: - Under voltage (insufficient voltage supply) can lead to reduced crane performance, causing motor overheating, erratic operation, or even system failures. Conversely, overvoltage (excessive voltage supply) can damage electrical components, posing safety hazards and increasing maintenance requirements.

- Mitigation Strategies for Voltage Variations: - Voltage regulators and stabilizers can help maintain consistent voltage levels, ensuring the crane operates within the prescribed voltage range. Additionally, installing surge protectors and employing regular maintenance checks aid in mitigating the adverse effects of voltage fluctuations, safeguarding the crane's electrical systems.

Understanding these voltage specifications and their potential impacts on crane performance lays the foundation for ensuring stable and reliable operations, emphasizing the need for proactive measures to manage voltage fluctuations effectively.

Electrical Systems in Crane Operations

Motors:

- Motors: These are the primary drivers of crane operations. They take electrical energy and convert it into mechanical motion to power the lifting, lowering, and movement of the crane. Different types of motors might be used based on the crane's requirements, such as hoisting motors, trolley motors, and bridge motors.

- Hoisting Motors: These motors are responsible for lifting and lowering the load. They provide the necessary mechanical force to hoist materials vertically.

- Trolley Motors: Trolley motors control the lateral movement of the crane along the beam or track. They move the trolley, allowing horizontal positioning of the load.

- Bridge Motors: Bridge motors are used to propel the crane along the bridge girder, enabling movement across the working area. They facilitate the crane's travel along the length of the structure.

Motors used in overhead cranes are often electric induction motors or, in some cases, synchronous motors. They are designed to provide the required power and torque to perform specific crane operations efficiently.

Drives (Variable Frequency Drives - VFDs):

- Variable Frequency Drives (VFDs): VFDs are critical components that control the speed and torque of the motors. By adjusting the frequency and voltage supplied to the motor, VFDs enable precise regulation of motor speed and performance. This allows for smoother acceleration, deceleration, and speed control, enhancing efficiency and reducing stress on the motor and mechanical components. VFDs also offer energy-saving benefits by matching motor speed with the load requirements.

Control Systems:

These overhead crane control systems oversee and manage the various functions of the crane. They utilize technology like programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other control devices to offer precise command execution, real-time monitoring, and coordination of the crane's movements and operations.

- Programmable Logic Controllers (PLCs): PLCs are industrial digital computers used to automate various crane functions. They receive input signals, process them according to pre-programmed logic, and generate output commands to control the motors, drives, and other crane operations.

- Human-Machine Interfaces (HMIs): HMIs provide a user-friendly interface for crane operators and maintenance personnel to interact with the control system. They display crucial information, status updates, and allow users to input commands or adjust parameters. HMIs enable real-time monitoring, diagnostics, and adjustments to optimize crane performance.

- Control Devices: These include switches, push buttons, joysticks, and other input devices used by operators to initiate specific crane movements or actions. They interface with the control system to execute commands accurately.

Control systems in overhead cranes coordinate and synchronize the operations of various motors and drives. They ensure precise and safe movement, monitoring load capacity, position accuracy, and providing alarms or shutdowns in case of abnormal conditions, enhancing overall operational efficiency and safety.

These components - Motors, Drives (VFDs), and Control Systems - form the core of an overhead crane's electrical system, working together to provide precise control, efficient movement, and safe operation of the crane in various industrial settings. Integration and proper functioning of these components are vital for the crane's performance, productivity, and safety.

Wiring and Distribution Systems:

Wiring

- Wiring: Acts as the nervous system of the crane's electrical system. It includes cables, connectors, and conduits that transmit electrical signals between different components, ensuring seamless communication and power transmission.

- Cables and Conductors: Cables are essential components carrying electrical power and signals throughout the crane's electrical system. These cables consist of conductors insulated with materials suitable for the crane's operating environment. Conductors can be made of copper or aluminum, depending on the application and load requirements.

- Connectors and Terminals: Connectors and terminals facilitate the connection and termination of cables at various components within the crane. Properly secured and insulated connectors ensure reliable electrical connections and minimize the risk of faults or disruptions in the power supply.

- Conduits and Cable Management: Conduits protect cables from physical damage, moisture, and environmental elements. They provide a pathway for the cables, ensuring organization, protection, and ease of maintenance. Cable management systems help in organizing and securing cables to prevent tangling or accidental damage.

Distribution Systems:

- Distribution Systems: Responsible for allocating and delivering electrical power to different crane components. This includes transformers, switchgear, circuit breakers, and distribution panels that manage the flow of electricity, maintain proper voltage levels, and ensure safety by protecting against overloads or faults.

- Transformers: Transformers change the voltage levels of electrical power to suit different crane components. They step up or step down the voltage as needed, ensuring that the electrical equipment receives the appropriate voltage levels for safe and efficient operation.

- Switchgear: Switchgear includes switches, fuses, and other control devices that control the flow of electricity within the crane's electrical system. They enable operators to isolate, control, and protect different sections of the electrical system.

- Circuit Breakers: Circuit breakers interrupt the flow of current in case of an overload or fault, protecting the crane's electrical system from damage due to excessive current. They are crucial safety devices that automatically trip and disconnect the circuit when necessary.

- Distribution Panels: Distribution panels serve as central points for distributing electrical power within the crane. They receive power from transformers and distribute it to various components, ensuring that different parts of the crane receive the required power supply at appropriate voltage levels.

- Monitoring and Protection Devices: Various monitoring devices, such as relays, sensors, and meters, may be integrated into the distribution system to monitor voltage, current, and other parameters. These devices provide valuable data for maintenance and protection against electrical faults.

The Wiring and Distribution Systems work in tandem to ensure the seamless transmission of electrical power, maintain proper voltage levels, and protect the crane's electrical components from faults, overloads, and other potential hazards. Regular inspections, proper installation, and adherence to safety standards are crucial for the efficient functioning of these systems in overhead cranes.

These components collectively form the foundation of the electrical systems in cranes, enabling them to perform lifting, moving, and positioning tasks efficiently and safely. Each component plays a crucial role in ensuring the proper functioning and control of the crane's electrical system, contributing to its overall reliability and performance.

Role of Electrical Systems in Crane Functionality:

- Ensuring Safety and Efficiency: - Electrical systems play a pivotal role in maintaining the safety and efficiency of crane operations. Properly functioning electrical components are crucial for preventing electrical hazards, ensuring stable performance, and safeguarding both personnel and equipment.

- Integration with Crane Controls and Operations: - The integration of electrical systems with crane controls is essential for smooth operation. These systems facilitate the implementation of precise commands, enabling operators to maneuver the crane effectively. Seamless integration ensures that electrical systems work harmoniously with the mechanical aspects of the crane, optimizing overall functionality.

The intricate interplay of motors, drives, control systems, wiring, and distribution networks underscores the critical role of electrical systems in the safe and efficient functioning of cranes. Understanding these components and their functions is paramount for ensuring reliability, safety, and optimal performance in crane operations.

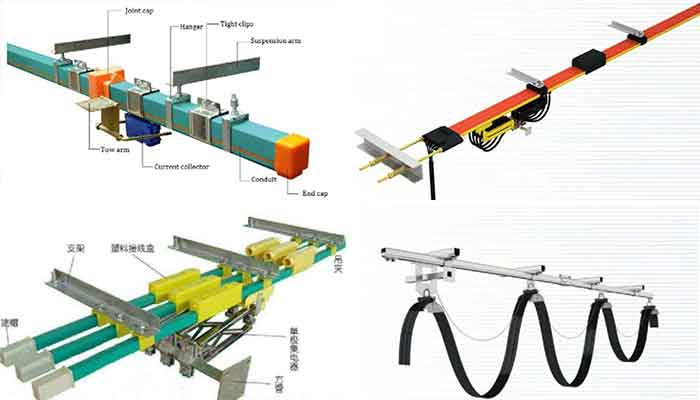

Electric Overhead Crane 4 Types of Power Supply Lines

Electric Overhead Crane 4 Types of Power Supply Lines

Frequency Considerations

Understanding Frequency Requirements for Crane Operations:

- Standard Frequency Specifications: - Crane operations often adhere to standard frequency specifications, such as 50 or 60 Hertz, depending on geographical locations or industry norms. Consistency in frequency supply is crucial for the synchronous functioning of the crane's electrical components.

- Implications of Frequency Deviations on Crane Performance: - Deviations from standard frequencies can significantly impact crane performance. Higher or lower frequencies than the prescribed standard may cause motor inefficiencies, affecting speed control and torque, potentially leading to erratic crane operation or equipment damage.

Frequency Converters and their Role in Crane Electrical Systems:

- Adapting to Different Grid Frequencies: - Frequency converters serve as vital components in crane electrical systems, enabling the adaptation of the crane's power supply to different grid frequencies. This capability allows cranes to operate seamlessly in regions or environments with varying frequency standards.

- Impact on Crane Operation and Efficiency: - The incorporation of frequency converters ensures the crane's adaptability to diverse frequency environments, enhancing operational flexibility. Moreover, by maintaining the prescribed frequency, these converters contribute to consistent crane performance, thereby improving efficiency and reducing the risk of electrical system-related issues.

The understanding of frequency requirements and the integration of frequency converters in crane electrical systems are pivotal in ensuring operational adaptability and maintaining optimal performance across varying frequency environments. Consistent frequency supply plays a vital role in mitigating potential issues and enhancing the efficiency and reliability of crane operations.

Impact of Electrical Systems on Crane Operation

Influence of Electrical Systems on Crane Performance:

- Reliability and Maintenance Considerations: - The reliability of electrical systems significantly affects crane performance. Well-maintained electrical components reduce the likelihood of unexpected breakdowns or malfunctions, ensuring consistent operation and minimizing downtime due to maintenance.

- Impact on Productivity and Downtime Reduction: - Efficient electrical systems contribute to enhanced productivity by facilitating smooth crane operations. Reliable electrical components result in reduced downtime, enabling seamless workflow continuity and optimized utilization of crane resources.

Importance of Proper Electrical System Design for Safe Crane Operations:

- Ensuring Compliance with Safety Standards: - Properly designed electrical systems adhere to stringent safety standards. Compliance with these standards ensures that electrical components meet necessary safety criteria, reducing the risk of electrical accidents or hazards during crane operations.

- Mitigating Risks Associated with Electrical Failures: - Robust electrical system design incorporates redundancy and failsafe mechanisms to mitigate risks associated with electrical failures. Implementing backup systems or automatic shutdown protocols in case of electrical issues helps prevent accidents and potential damage to personnel or equipment.

The influence of electrical systems on crane performance underscores the need for reliability, maintenance, and safety considerations. Prioritizing proper design, adherence to safety standards, and contingency planning within electrical systems ensures safe and efficient crane operations, reducing downtime and optimizing productivity.

Electrical Protection

Electrical protection refers to the measures, devices, and systems implemented to ensure the safety and reliable operation of electrical equipment, preventing damage, hazards, or malfunctions that can result from various factors such as overcurrent, overvoltage, short circuits, environmental conditions, and more. The electrical protection for overhead cranes typically refers to the measures and standards in place to safeguard the electrical components of the crane from various environmental factors, potential hazards, and ensure safe operation. It involves the use of specific enclosures, devices, and adherence to standards that protect the electrical system of the crane.

There are several aspects to electrical protection, including protection devices and protection levels:

Protection Devices:

- Circuit Breakers: These devices automatically interrupt electrical circuits in the event of overcurrent, preventing damage to the electrical system. They come in various types (such as thermal, magnetic, or hybrid) and sizes depending on the application.

- Fuses: Similar to circuit breakers, fuses break the circuit when there's an excessive current flow. They consist of a wire or strip that melts to interrupt the flow of electricity, protecting the system.

- Relays: Used to control and protect circuits by opening or closing contacts in response to electrical signals. They can be used for overload protection, phase failure, or other specific protections.

- Surge Protectors: Safeguard against voltage spikes or transient surges that could damage sensitive electrical equipment. They divert excess voltage to the ground, protecting the connected devices.

- Ground Fault Circuit Interrupters (GFCIs): These devices quickly shut off power to a circuit if they detect a ground fault, preventing electric shock or fire hazards, commonly used in areas with water exposure.

- Overload Protection Devices: Typically in the form of relays or electronic devices, they safeguard electrical systems from excessive current and prevent damage to components.

Protection Levels:

- a. IP Ratings (Ingress Protection): IP ratings indicate the level of protection provided by enclosures against intrusion from solids and liquids. The ratings consist of two digits; the first denotes protection against solids, and the second against liquids. Higher numbers indicate higher protection levels.

- b. NEMA Standards: NEMA classifications specify the level of protection provided by electrical enclosures against environmental factors like moisture, dust, corrosion, and more. Higher NEMA ratings offer greater protection.

- c. Hazardous Area Classifications: Electrical equipment intended for use in hazardous environments (e.g., explosive atmospheres, flammable gases) requires specific protection levels based on classifications such as Class I, II, or III.

These protection devices and levels ensure the safe and reliable operation of electrical systems, safeguarding equipment, preventing hazards, and complying with industry standards and regulations. The selection of protection devices and levels depends on the specific requirements of the electrical equipment, the environment it operates in, and the applicable regulations and standards.

How to Select Electric Protection for Your Overhead Cranes

Selecting the appropriate electrical protection level for a crane in a specific work environment involves assessing various factors related to safety, operational requirements, regulations, and environmental conditions. Here are steps to help in choosing the right electrical protection level for a crane:

- Understand Regulatory Requirements: - Familiarize yourself with local, national, and industry-specific regulations and standards governing crane electrical safety. These standards often outline the minimum safety requirements and protection levels necessary for crane operations.

- Risk Assessment: - Conduct a comprehensive risk assessment of the work environment where the crane operates. Identify potential hazards related to electrical systems, such as exposure to moisture, dust, temperature extremes, and the presence of flammable or explosive substances.

- Environmental Conditions: - Consider the environmental factors that could affect the electrical components of the crane. For instance, outdoor environments might require additional protection against moisture, while indoor operations might face different challenges like dust or corrosive substances.

- Select Appropriate Enclosures and Protection Devices: - Based on the risk assessment and environmental factors, choose enclosures and protection devices that comply with the required protection level. Enclosures might include IP (Ingress Protection) rated housings, NEMA (National Electrical Manufacturers Association) enclosures, or specific protective measures for wiring and electrical components.

- IP and NEMA Ratings: - IP and NEMA ratings provide guidance on the degree of protection against intrusion of solids and liquids for electrical enclosures. Higher IP or NEMA ratings signify better protection. Select the appropriate rating based on the environmental conditions the crane will be exposed to.

- Consider Equipment Classifications: - Certain hazardous environments, such as those with flammable gases or vapors, might require equipment with specific classifications, such as Class I, II, or III for potentially explosive atmospheres. Ensure that the crane's electrical components meet the necessary classifications.

- Consult Manufacturers and Experts: - Seek advice and guidance from crane manufacturers, electrical engineers, or safety experts. They can provide insights into the appropriate protection levels based on the crane's specifications, environmental considerations, and regulatory requirements.

- Regular Maintenance and Inspection: - Implement a schedule for regular maintenance and inspection of the crane's electrical components. Ensure that protective measures are functioning correctly and are not compromised due to wear, damage, or environmental factors.

- Training and Safety Procedures: - Train personnel operating the crane on safety protocols and procedures related to electrical systems. Emphasize the importance of following safety guidelines and promptly reporting any signs of electrical issues or malfunctions.

By considering these factors and conducting a thorough assessment, you can determine the appropriate electrical protection level for a crane in a specific work environment, ensuring both safety and operational efficiency.

Electrical Equipment Maintaining of Overhead Cranes

Maintaining electrical equipment for overhead cranes is critical to ensure safe and efficient operation. Here are some key aspects of electrical equipment maintenance for overhead cranes:

- Regular Inspections: Conduct routine inspections of electrical components, including motors, drives, control panels, wiring, and connections. Look for signs of wear, corrosion, loose connections, or any visible damage that might compromise the functionality or safety of the crane.

- Cleaning and Lubrication: Keep electrical components clean and free from dirt, dust, or debris. Regularly clean motors, control panels, and other electrical parts to prevent accumulation that can lead to overheating or malfunction. Lubricate moving parts as per manufacturer guidelines to ensure smooth operation and prevent premature wear.

- Testing and Calibration: Periodically test and calibrate sensors, limit switches, and safety devices to ensure they are functioning correctly. This includes load sensors, position sensors, emergency stop switches, and other safety features critical for the crane's safe operation.

- Check for Overloads and Overcurrents: Monitor and analyze the electrical system for signs of overloads or overcurrents. Use protective devices like fuses, circuit breakers, and overload relays to prevent damage due to excessive current flow.

- Inspect Cables and Wiring: Check cables, wiring, and connectors for signs of wear, fraying, or damage. Ensure that all connections are secure and properly insulated to prevent short circuits or electrical faults.

- Review Maintenance Records: Maintain detailed records of maintenance activities, including inspections, repairs, and replacements. These records help in tracking the history of electrical equipment, identifying recurring issues, and planning preventive maintenance.

- Compliance with Standards: Ensure that all electrical equipment complies with relevant industry standards, local regulations, and manufacturer recommendations. This includes using appropriate enclosures, protection devices, and following specified maintenance intervals.

- Training and Awareness: Train crane operators and maintenance personnel on electrical safety protocols, proper handling of equipment, and recognizing potential electrical hazards. Encourage reporting of any abnormal behavior or signs of electrical issues.

- Emergency Preparedness: Have contingency plans in place for power failures or electrical malfunctions. Ensure that emergency stop switches and other safety features are readily accessible and functioning correctly.

- Scheduled Preventive Maintenance: Implement a proactive maintenance schedule that includes routine checks, preventive measures, and scheduled downtime for comprehensive inspections and necessary repairs.

By implementing a robust maintenance strategy for electrical equipment in overhead cranes, you can significantly reduce the risk of downtime, improve safety, and extend the lifespan of the crane while ensuring its reliable operation. Regular inspections, adherence to maintenance schedules, and prompt repairs are essential to maintain peak performance and safety standards.

The intricate interplay between voltage requirements and electrical systems forms the backbone of efficient and safe crane operations. Voltage specifications dictate the optimal power input necessary for crane functionality, while electrical systems encompass a myriad of components crucial for seamless operation. Understanding these aspects is fundamental to mitigating risks associated with voltage fluctuations and ensuring consistent performance.

Properly designed electrical systems play an indispensable role in guaranteeing the efficiency and safety of crane operations. From motors and control systems to wiring and distribution networks, every element contributes to the crane's overall functionality. Reliability, adherence to safety standards, and proactive maintenance measures within these systems are imperative for minimizing downtime, enhancing productivity, and safeguarding both personnel and equipment.

In essence, comprehending voltage requirements and maintaining robust electrical systems are not merely technical necessities but are pivotal for the success of crane operations. The significance of these aspects cannot be overstated, as they are intrinsic to the safe, efficient, and uninterrupted functioning of cranes across various operational landscapes.

Good Price Electric Crane and Electric Hoists

0.25 ton - 550 ton Electric Overhead Cranes & Electric Gantry Crane for Sale

Hot Sale Electric Hoists & Cranes

European style single girder electric overhead crane

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.Good price overhead travelling crane 1-stop service.

Suspension electric Crane

Single girder underhung bridge cranes & underslung cranes:1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEN standard open winch electric overhead crane

FEM/ DIN open winch bridge crane: European winch trolley, Heavy duty hook cranes:European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton, wide specifications hook cranes for wide application. Get FEM/ DIN open winch bridge crane now!

A frame electric gantry crane

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling. Good price European gantry cranes for sale.

Double girder electric gantry crane

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale, good gantry crane price.

Floor mounted slewing electric jib crane

Free standing jib crane- Pillar jib crane design, floor mounted jib crane:Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton. Get pillar mounted jib crane design now!

Wall mounted electric jib crane

Wall mounted jib crane & wall bracket jib crane - Wall crane :Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes. Wall mounted jib crane for sale.

KBK rail light electric crane

Light crane kbk system: Flexible & rigid kbk modular cranes: kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.125kg to 5000kg kbk crane systems for sale.